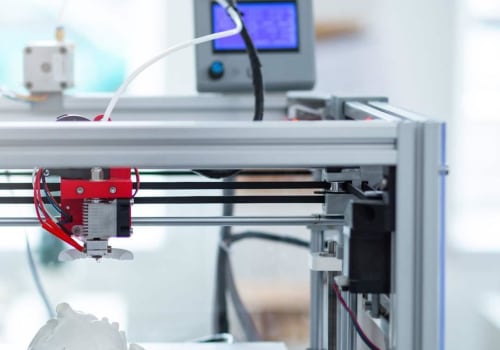

Wallace, on low-concentration inks formulated with nanocellulose assisted with gelatin methacrylate (GelMA) for 3D printing for wound healing purposes. Liska, Rapid formation of regulated methacrylate networks that produce resistant materials for 3D printing based on lithography. Extrusion-based technology is another promising technology in the field of 3D printing, which is now widely used to manufacture scaffolding for fabric engineering. In addition, the usefulness of non-toxic polymeric materials for 3D printing helps reduce the generation and emission of toxic particles and volatile organic compounds (VOCs).

First, different types of biocompatible materials are introduced, followed by different 3D printing techniques and their usefulness in the manufacture of biocompatible materials. Most of the materials were specifically intended for dental applications, followed by general medical use and then for specific medical applications. Over the past thirty years, the medical community has increasingly adopted 3D printing to create devices for patients that require fast and personalized solutions. Multi Jet Fusion (MJF) technology is quickly becoming a popular choice for 3D printing prototypes and production parts.

Alginate hydrogels, for example, have the appropriate gelation times required in 3D printing, but they have been found to have undesirable degradation properties in vivo, while other, more biodegradable polymers could be manufactured to achieve the correct gelation times through ultraviolet (UV) cross-linking. Panoramic 3D printing of mechanically stable calcium alginate-based calcium alginate-based scaffolding without calcium alginate with adjustable surface load to allow cell adhesion and facilitate biofunctionalization. 3D metal printing technology, also known as direct metal laser sintering (DMLS) and direct metal laser fusion (DMLM), is a technology for manufacturing metal-based additive layers. DLP has processed different biomaterials, from biopolymers and bioceramics to various biocomposites, for possible medical applications.

The biocompatible MED625FLX, MED610 and MED620 are ideal for medical and dental applications that require precise visualization and patient contact. Weisman, Studies on the cytocompatibility, mechanical and antimicrobial properties of 3D printed poly (methyl methacrylate) beads. Zhang, Integrating biologically inspired nanomaterials and tabletop stereolithography for 3D printed biomimetic osteochondral scaffolds.