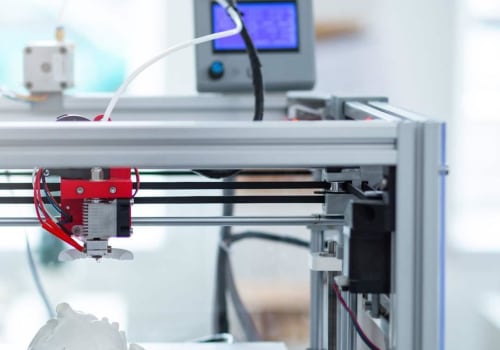

Instruments printed in 3D and matched with patients provide medical device representatives with the opportunity to present tools that allow for faster and more accurate surgeries. This allows medical device companies to give surgeons confidence by providing the right tools and implants for anatomical alignment. The use of 3D printing also helps reduce the inventory needed for surgery, reducing costs and preoperative barriers. Every year, 3D printing offers more and more applications in the field of health that help save and improve lives in ways never imagined before.

The growing surgical applications of 3D printing have made it interesting to analyze the current implementation of this new technology. The advantages of 3D printed surgical instruments expressed in their article were customization and ease of modification according to the doctor's preferences. In some clinical scenarios where 3D printing could be used, such as the printing of an anatomical model that is used to plan surgery or perhaps one day the printing of human tissue for transplantation, it is not always easy to distinguish between product and practice. For example, research is underway to use 3D printing to manufacture pharmaceutical products with the possibility of creating unique dosage forms or formulations, including those that could allow for slower or faster absorption. The growing surgical applications of 3D printing have made it interesting to analyze the current implementation of this new technology. The advantages of 3D printed surgical instruments expressed in their article were customization and ease of modification according to the doctor's preferences. In some clinical scenarios where 3D printing could be used, such as the printing of an anatomical model that is used to plan surgery or perhaps one day the printing of human tissue for transplantation, it is not always easy to distinguish between product and practice. For example, research is underway to use 3D printing to manufacture pharmaceutical products with the possibility of creating unique dosage forms or formulations, including those that could allow for slower or faster absorption.

Enwatch's PMI application uses artificial intelligence to transform 2D medical images into 3D anatomical models. The FDA has also approved software programs specifically designed to generate 3D models of a patient's anatomy20; however, it is up to the actual medical center to use that software within the scope of its intended use and to use it correctly. More comprehensive cost-effectiveness studies would be needed to assess the acceptability of the technology, both for complex cases and for routine cases that use 3D printing. This allows for fast and seamless collaboration between the medical device company and the surgical team.

In addition to the benefits mentioned above, anatomical models can be used to teach medical students and can improve patient communication and knowledge of pathology. Most class II devices undergo what is known as a 510 (k) revision (named after the corresponding section of the Federal Food, Drug and Cosmetic Act), in which the manufacturer demonstrates that their device is “substantially equivalent to an existing device on the market, reducing the need for extensive clinical research.” An example of the application of 3D printing in the treatment of pediatric congenital heart diseases is a study published in the literature based on the development of a 3D cardiac model of a 15-year-old child to improve simulation and intervention planning in patients with aortic arch hypoplasia. Among the different manufacturing processes currently being adopted by the industry, 3D printing is an additive technique. In addition, anatomical models of the mouth are used to make drilling guides for dental implants and to make customized obturators for patients after maxillectomy.

In both cases, doctors can use 3D printing to make products that specifically match the patient's anatomy.