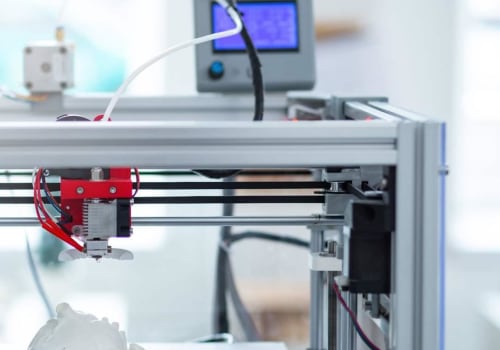

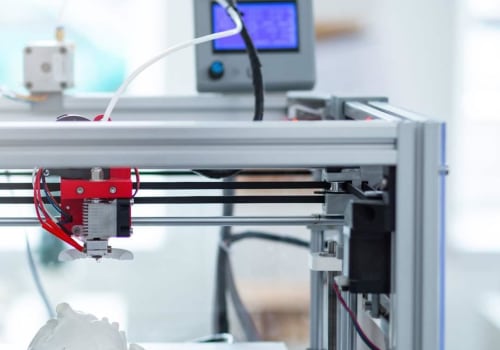

The biggest advantage that 3D printers offer in medical applications is the freedom to produce tailor-made medical products and equipment. 3 For example, the use of 3D printing to customize prostheses and implants can offer great value for money to both patients and doctors. 3 In addition, 3D printing can produce custom-made templates and accessories for use in operating rooms, 4 Custom-made implants, accessories and surgical tools can have a positive impact in terms of the time required for surgery, patient recovery time and the success of surgery or implant, 4 It is also expected that 3D printing technologies will eventually allow customization of dosage forms, release profiles and drug delivery profiles for each patient. 5.Johnson & Johnson (J&J), one of the largest manufacturers of medical devices and pharmaceutical products in the world, is at the forefront of innovation in 3D printing.

For a promising future, multimaterial composites seem to represent a good opportunity for 3D printing of human tissues, since none of the materials currently available are capable of fully imitating elastic and biological tissues. Among the different manufacturing processes currently being adopted by the industry, 3D printing is an additive technique. This growth is likely to lead to greater use of 3D printing in both clinical and educational environments, clearer regulatory guidance, and greater competition among medical device manufacturers. Implantable drug delivery devices with new drug delivery profiles can also be created using 3D printing.

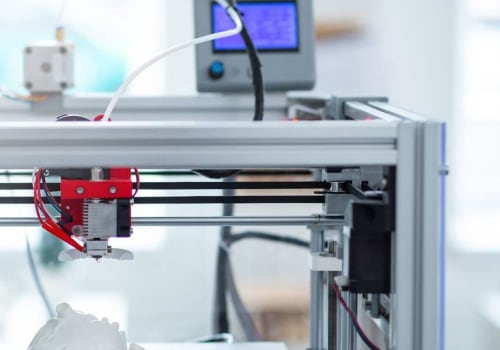

You can use magnetic resonance imaging, X-ray computed tomography, and other 3D imaging processes to create digital models of structures for printing. The three main pillars of this new technology are the ability to treat more people where it wasn't feasible before, obtaining results for patients and reducing the time required in the direct case of medical specialists. From a design point of view, 3D printing allows the creation of prostheses with unique characteristics that are not possible with traditional manufacturing methods. Just as printing radically transformed the publishing industry, 3D printing is about to revolutionize supply chains in all sectors.

Complex drug manufacturing processes could also be standardized by using 3D printing to make them simpler and more viable. Another beneficial feature offered by 3D printing is the democratization of product design and manufacturing. I consider 3D printing to be a competitive advantage, provided that the companies that use it can seamlessly integrate it into their current operations. Today, 3D printing technology represents a great opportunity to help pharmaceutical and medical companies create more specific drugs, allowing rapid production of medical implants and changing the way doctors and surgeons plan procedures.