The following are the steps you can take to protect your facilities and your workers from potential health hazards from 3D printing. To protect all workers involved in 3D printing, it is essential that organizations become familiar with the specific health risks involved and how to combat them properly through the use of appropriate practices and personal protective equipment (PPE). If you don't have an isolated cabinet for printing equipment, select a room or location that has high airflow, windows that can work, and outdoor outlets. While the popularity of 3D printing has grown, many health hazards of 3D printing are just beginning to be recognized.

While 3D printing seems relatively safe, a deeper analysis shows that the compounds, chemicals and materials used and emitted during printing are hazardous. These health problems are especially noticeable when 3D printers are used in small or poorly ventilated rooms, such as small workshops or individual workstations and large industrial spaces with several operating printing units and insufficient ventilation control. To date, 3D printers have been introduced in numerous environments, including medical laboratories, automotive parts manufacturers, electronics manufacturers, and even the aerospace industry. Contact a Cybernet expert if you're interested in learning more about 3D printing in healthcare and why its benefits outweigh the disadvantages.

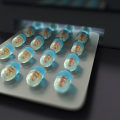

In addition, appropriate security measures, such as the regulation of 3D printer manufacturing, will reduce risks for both patients and medical organizations. General dust masks are not designed to block the particles that are often released during 3D printing processes. In a survey conducted by industrial 3D printing solutions provider Essentium, 85% of manufacturers reported that industrial-scale additive manufacturing has the potential to increase their business revenues. A 3D printer for medicines on-site in a hospital can make printing easier for your patients when needed.

These nightmarish situations and more can be applied to health organizations that print their own medical devices, such as syringes, on human tissue, such as ligaments and tendons. While watching a 3D printer in action is interesting, employees shouldn't spend more time than necessary near the operational 3D printer. To protect the eyes from small particles and from potential chemical splashes, employees should always wear protective goggles when using 3D printing equipment.