Common applications of 3D printing in healthcare Models allow doctors to understand the anatomy of patients that is difficult to visualize, especially when using minimally invasive techniques. The models also help to precisely size medical devices. The ease of use and low cost of in-house 3D printing have also revolutionized product development, and many manufacturers of medical tools have adopted this technology to produce completely new medical devices and surgical instruments. From surgical planning models to 3D printed vasculature and bioreactors, read on to discover five ways in which 3D printing is taking off in healthcare and why many medical professionals are excited about the potential of 3D printing in the medical field.

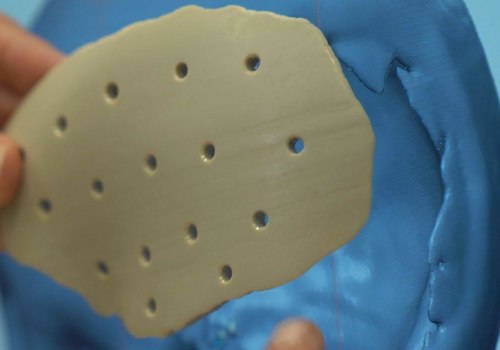

In the case of medical 3D printing that is performed outside the scope of FDA regulation, there is little formal oversight. DMLS and SLM 3D printers can create tough, precise and complex metal products, making this process ideal for a variety of medical applications. Jonathan Morris, co-director of the Anatomical Modeling Laboratory and neuroradiologist at the Mayo Clinic, shares the history of 3D printing in medicine and examines real case studies of how radiologists have successfully introduced 3D printing capabilities and programs in hospitals. SLS 3D printing is ideal for robust and functional prototypes and end-use parts, such as prostheses and orthopedic appliances.

With Draft Resin, Formlabs' SLA printers are also the fastest options for printing large prototypes in 3D, up to 10 times faster than FDM. Alternatively, SLA 3D printing is ideal for casting workflows that produce metal parts at a lower cost, with greater design freedom and in less time than traditional methods. One of the main advantages of 3D printing is that it does not require the cumbersome and expensive equipment needed in traditional manufacturing, which greatly accelerates the speed of production of products. While 3D printing presents significant opportunities for clinical innovation, many institutions face reimbursement and security issues related to the integration of rapidly evolving technology in a highly regulated field.

However, when 3D printing is used to manufacture a medical product at the point of care, oversight responsibility may become less clear. Professionals around the world are using 3D printing to reinvent specific insoles and orthoses for patients and clients, as well as a range of other tools to improve physical therapy. The simple 3D printing service provides patients with low-cost, individualized prostheses, implants and devices, allowing surgeons to operate more effectively with customized equipment and models, and helping medical device manufacturers to develop new and faster products. Initiatives such as e-NABLE allow entire communities around the world to learn about 3D printed prostheses.