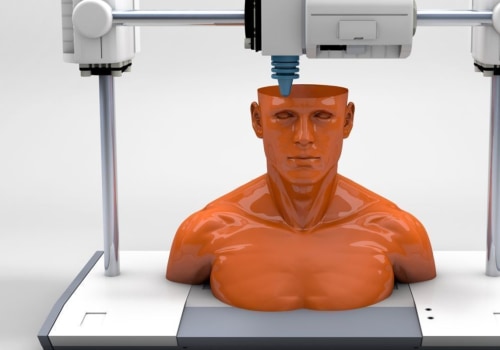

Additive manufacturing for the healthcare sector is still a work in progress, but it is already being applied in many different ways in the field of medicine, which, which is already under enormous pressure in terms of optimal performance and cost reduction, will achieve unprecedented benefits thanks to this technology as good as gold. GlaxoSmithKline has also shown interest in Additive manufacturing for the healthcare sector is still a work in progress, but it is already being applied in many different ways in the field of medicine, which, which is already under enormous pressure in terms of optimal performance and cost reduction, will achieve unprecedented benefits thanks to this technology as good as gold. GlaxoSmithKline has also shown interest in 3D printing of drugs, and has collaborated with the University of Nottingham in a study that used nozzle printing and ultraviolet curing to produce 3D printed ropinirole tablets to treat Parkinson's disease. As printers evolve, the safety of printing biomaterials is being regulated and the general public gains common sense about how 3D printing works. Scientists are investigating how to use the 3D printing process to manufacture living organs such as the heart or liver, but this research is in the early stages of development.

For a promising future, multimaterial composites seem to represent a good opportunity for 3D printing of human tissues, since none of the materials currently available are capable of fully imitating elastic and biological tissues. The DOE has collected information on how 3D printing works, the different types of printers and what they are used for. Each specific case in which 3D printing has found an application that is shown in this analysis is a demonstration of that. Another proposed study in which 3D printing played an important role consists of a preoperative clinical evaluation of five patients between 7 months and 11 years of age affected by a double-outlet right ventricle with two well-developed ventricles and a remote ventricular septal defect.

This analysis presents an overview of the application of 3D printing in the field of medicine, highlighting its usefulness and limitations and how it could be useful for surgeons. The FDA regulates 3D printed medical devices in the same way as traditional medical devices; therefore, they are evaluated according to the safety and efficacy information provided to us by the manufacturer. For more information on how 3D printers work and the different printing technologies, visit the DOE's How 3D Printers Work website. Pharmaceutical companies must adopt new technologies, such as 3D printing, to carry out more personalized treatments, improve the efficiency of R&D, reduce costs and minimize waste.

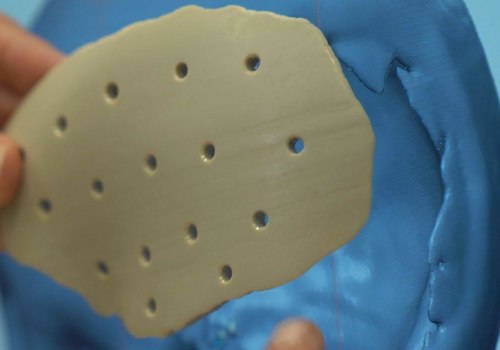

The materials used in 3D printing are transformed during the production of the specific model by changing their consistency. 3D printing in the field and design of medicine must go beyond the ordinary to change healthcare. For example, the specification may define a minimum and maximum wall thickness or how steep a curve can be to maintain the performance of the device for its intended use. ZipDose technology uses a droplet printing technique on a solid, in which a printing nozzle deposits drops of a liquid binding agent onto a bed of free pharmaceutical powder, unifying the powder in a free form where it falls.